You’ll pick a piston inflator when you need fast, high‑pressure fills and a diaphragm inflator when you want quieter, gentler, longer‑lasting inflation. Piston pumps use a sliding piston in a sealed cylinder to deliver strong, pulsed airflow and reach higher PSI quickly, while diaphragm pumps flex a membrane to pull and push air for smoother, steadier pressure and better tolerance of dry or varied gases. Choose based on speed vs quiet control, and keep going to learn specifics.

Quick Pick: Piston vs Diaphragm Tire Inflators – Which to Buy

Which inflator should you pick depends on what you need to inflate and how fast you want it done. You’ll choose piston pumps when you need high pressure and quick fills—ideal for car tires and portable tire inflators where forceful air output matters. You’ll opt for diaphragm pumps when you prioritize quieter, compact gear that’s easier to maintain and excels in applications requiring deep vacuum levels or consistent, gentle airflow for delicate tasks. Consider use: high-pressure tasks, roadside fixes, and heavy-duty inflations favor pistons; home projects, small inflatables, and noise-sensitive environments favor diaphragms. You’re aiming for liberation from downtime and noise, so match the tool to the task: pick power and speed for demanding jobs, choose versatility and smooth operation for everyday convenience. Keep scope clear—don’t overbuy features you won’t use; buy the pump that frees you to move again, fast and with confidence.

Why That Pick? Short Pros & Cons at a Glance

Because you’re deciding quickly, here’s a tight breakdown: piston inflators deliver fast, high-pressure fills and compact portability but wear faster and can be louder; diaphragm inflators run quieter, last longer, and give gentler, more consistent airflow at the cost of peak pressure and speed.

If you want speed, go piston pumps and diaphragm contrast: piston positive displacement pumps generate high pressure quickly, perfect for rapid tire topping and on-the-go fixes. They’re compact and portable, but sliding friction limits life to a few thousand hours and they’re noisier. If you want durability and finesse, choose diaphragm. Diaphragm positive displacement pumps offer a quieter, longer-lived option (often 10,000+ hours) and provide a good vacuum and steady, controlled flow—ideal for delicate inflations and wider fluid compatibility. You’ll trade some peak pressure and fill speed for longevity and smoother operation. Pick based on whether liberation for you means speed now or dependability over time.

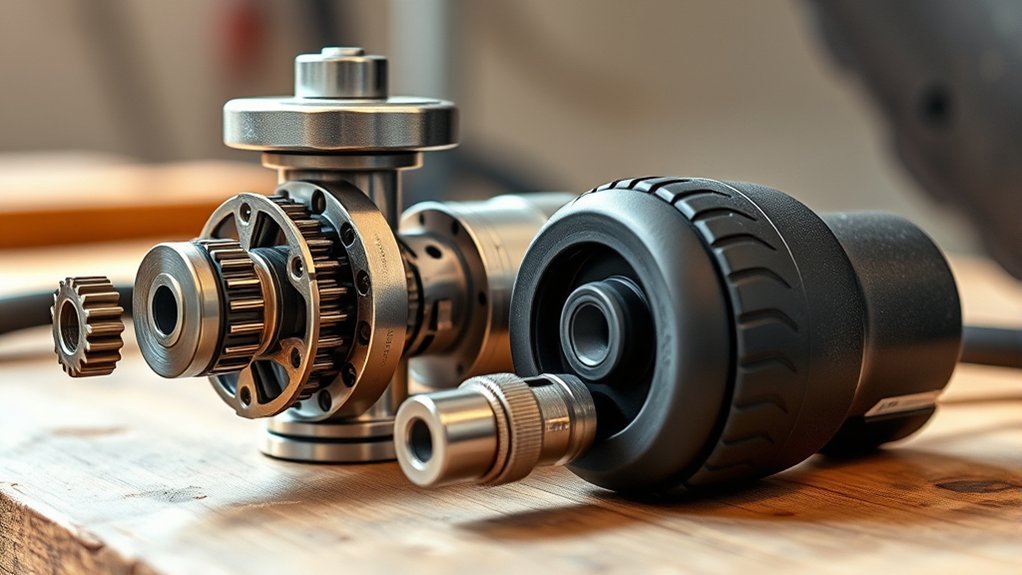

How Piston and Diaphragm Inflators Work (Simple Explainer)

You’ll see a piston pump pressurize air by driving a piston down a cylinder to force large volumes quickly into the tire, which is why it’s favored for high-pressure, high-flow jobs. A diaphragm pump, by contrast, flexes a membrane to alternately draw air in and push it out, running quieter and tolerating intermittent use or different gases. Understanding those basic mechanics helps you pick the right tool for speed, portability, or duty cycle.

Piston Pump Mechanics

When you look inside a piston tire inflator, you’ll find a piston sliding within a sealed cylinder that draws in air on the intake stroke and forces it out at high pressure on the compression stroke. You’ll appreciate how piston pumps deliver focused, high-pressure airflow for fast inflation and precise control. They need lubrication to reduce sliding wear and can’t run dry without risking damage and loss of performance. Expect shorter service life (≈2,500–5,000 hours) versus diaphragm units, but greater effectiveness with dense media.

- High-pressure delivery enables quick tire fill.

- Precise stroke control gives repeatable pressure results.

- Lubrication is mandatory to prevent accelerated wear.

- Design favors robustness for thicker materials, less versatility for light-duty tasks.

Diaphragm Pump Operation

Having seen how piston pumps use a sliding cylinder and lubrication to deliver high-pressure airflow, you can now look at diaphragm inflators as an alternative that trades piston mechanics for flexible membrane action. Diaphragm pumps move a flexible diaphragm back and forth, creating a partial vacuum that draws air into a chamber, then compressing to force air into the tire. You’ll appreciate that this design yields superior performance in several ways: strong vacuum generation for quick inflation, the ability to run dry without damage, and quieter operation suited to shared spaces. Construction also tolerates various gases, so you can choose working fluids without worry. For a liberated, low-noise workflow, diaphragm inflators are a practical, efficient choice.

Performance Compared: Flow, Max PSI, Speed, Consistency

Although both types swell a tire, piston and diaphragm inflators serve different performance needs: piston units push higher peak PSI (often 100–150 PSI) and faster flow for quick fills, while diaphragm units top out lower (around 70–100 PSI) but deliver steadier, more consistent airflow useful for precision or prolonged inflation. You’ll choose based on what you value: raw flow rate and max psi for speed, or steadiness and control for repeatable results.

- Flow rate — piston: high, fills in ~2–5 minutes; diaphragm: lower, slower but smooth.

- Max PSI — piston achieves 100–150 PSI; diaphragm generally caps near 70–100 PSI.

- Speed — piston wins for rapid bulk inflation; diaphragm suits gradual, controlled fills.

- Consistency — diaphragm provides steadier pressure over time; piston can pulse at high output.

You want liberation from worry: match the pump to the task. Use pistons for fast, high-pressure needs and diaphragms when consistency and finesse matter.

Who Should Use Each Type : Drivers, Cyclists, Fleets, Roadside Kits

Think about what you need: if you want quick inflation for car or fleet tires, you’ll lean toward piston models for speed and durability. If you need portability and fine pressure control for bike tires or a compact roadside kit, diaphragm units fit better. Match the tool to your tire size, frequency of use, and whether portability or ruggedness matters most.

Quick Inflation Needs

When you need fast, high-pressure inflation for cars, trucks, or fleet vehicles, a piston inflator delivers the speed and force required, while diaphragm models suit cyclists and emergency roadside kits because they’re lighter, quieter, and gentler on narrow or delicate tires. You want tools that free you from delay and complexity: piston,diaphragm,quick inflation choices map to different needs.

- Drivers — Choose piston for rapid fill of larger tires; it cuts roadside time.

- Cyclists — Use diaphragm for portability and safe, low-impact inflation.

- Fleets — Standardize on piston to minimize downtime and boost throughput.

- Roadside kits — Include a diaphragm for quiet, simple fixes and a piston for heavy-duty emergencies.

Pick with intent; match output to the mission.

Precision Pressure Control

How much precision do you need for the task at hand? You’ll choose pumps based on pressure needs: piston or diaphragm. Piston inflators give superior precision pressure control at high PSI, so drivers and fleets get fast, accurate fills for larger tires and high-volume work. Cyclists and roadside kits favor diaphragm units for their low-pressure finesse, lightness, and self-priming convenience.

| User | Best Type | Why |

|---|---|---|

| Drivers | Piston | Accurate high-PSI control |

| Cyclists | Diaphragm | Lightweight, low-pressure fit |

| Fleets | Piston | Robust, rapid multi-vehicle use |

| Roadside Kits | Diaphragm | Compact, emergency-ready |

Choose the pump that matches your freedom to move: precision where it matters, simplicity where it frees you.

Portability And Durability

Because portability and durability often pull in opposite directions, pick the inflator that matches how and where you’ll use it: choose piston units if you need rugged, high-capacity gear that withstands frequent, heavy use (drivers and fleets), and go with diaphragm models if you want lightweight, compact, and forgiving backup tools for cyclists or roadside kits. You’ll want to match mission and tool: piston pumps handle high-pressure, high-duty cycles and even denser, highly viscous conditions in some service gear; diaphragm pumps give you portability and durability as a compact backup that tolerates running dry. Consider these use-case checkpoints:

- Drivers: piston for speed, longevity.

- Fleets: piston for reliability and lifespan.

- Cyclists: diaphragm for light carry.

- Roadside kits: diaphragm for resilience.

What Specs to Compare When Shopping: Motor, L/min, Max PSI, Duty Cycle

Although the right specs depend on your use, focus first on four things: motor type, flow rate (L/min), max PSI, and duty cycle. You’ll want a brushless motor if longevity matters — expect 8,000+ hours versus 2,500–5,000 for brushed motors. Motor choice affects reliability, heat and maintenance, so pick one that matches how often you’ll inflate.

Flow rates determine speed: models run from about 3 L/min to 25+ L/min. Higher flow rates save time on large tires and frequent use. Check max psi next; piston units usually hit higher pressures (often over 100 PSI), so choose based on tire size and load needs. Finally, evaluate duty cycle: a 50% duty cycle means 15 minutes on, 15 minutes off — plan around required run times to avoid overheating. Don’t forget weight and portability if you move gear often; the specs should free you, not slow you down.

Common Problems & Fast Troubleshooting for Each Pump Type

Once you’ve compared motor type, flow, max PSI and duty cycle, you’ll want to know what can go wrong in the field and how to fix it fast. You’ll face different common problems with pumps and piston pumps, and you should be ready with fast troubleshooting steps to keep moving.

- Check seals and diaphragms: worn seals in piston pumps and torn diaphragms cut output—replace parts immediately.

- Inspect intake filters: clogged filters reduce airflow; clean or swap filters to restore efficiency.

- Monitor heat and duty: continuous operation overheats both types—pause to cool per duty specs to avoid damage.

- Verify power and wiring: loose connections or bad power stops inflation—secure terminals and test the source.

You’ll act decisively: diagnose leaks, swap consumables, cool the unit, and confirm electrical integrity. That protocol frees you from downtime and preserves performance in the field.

Frequently Asked Questions

Can These Inflators Run on Battery Power or Require External Power?

Yes — you can power many inflators via batteries; you’ll check battery compatibility, alternative power sources, and charging options. You’ll choose portable models with built-in batteries or ones accepting external power for freedom and flexible use.

How Noisy Are Piston Versus Diaphragm Inflators During Operation?

Piston units are louder; diaphragm ones run quieter. You’ll get a clear noise levels comparison, learn simple sound dampening techniques, and read user experience feedback that empowers you to choose gear freeing your ride from disruptive clatter.

What Maintenance Schedule Extends Each Pump’s Lifespan?

You should inspect seals weekly, change oil or check diaphragms monthly, clean filters bi‑monthly, and perform annual full servicing; maintenance tips focus on longevity factors and adjust by usage frequency to maximize reliability and empower your independence.

Are There Size or Weight Differences for Travel and Storage?

Like a folded map promising escape, you’ll find piston units bulkier and heavier while diaphragms favor compact design; you’ll appreciate travel convenience and storage efficiency from diaphragms, though check specs for weight and durability trade-offs.

Do Either Type Handle High-Temperature or Cold Environments Well?

Yes — you can expect differing temperature performance: piston pumps tolerate heat but need oil; diaphragm pumps handle cold better. You’ll value environmental adaptability and material durability; choose models with rated seals and alloys for reliable liberation.

Conclusion

You now know the practical differences between piston and diaphragm inflators, so you can pick the right tool for your needs. If you want raw power and fast fills, choose piston; if you want lighter weight and better seal resistance, pick diaphragm. Think of the choice like selecting a work boot versus a running shoe—each excels at different tasks. Check motor specs, L/min, max PSI and duty cycle to match performance to purpose.

Leave a Reply