A Presta valve is the slim, threaded valve you’ll find on high-pressure, lightweight bike wheels, especially road and performance rims. You’ll unscrew the small lock nut to let air in or out, use a compatible pump head or adapter, and reseal it to hold pressure tightly. Its narrow diameter preserves rim strength and allows precise inflation. You’ll also learn quick maintenance tips, differences from Schrader valves and when to use extenders or removable cores for tubeless setups.

What Is a Presta Valve, and Why Is It Used on Bikes?

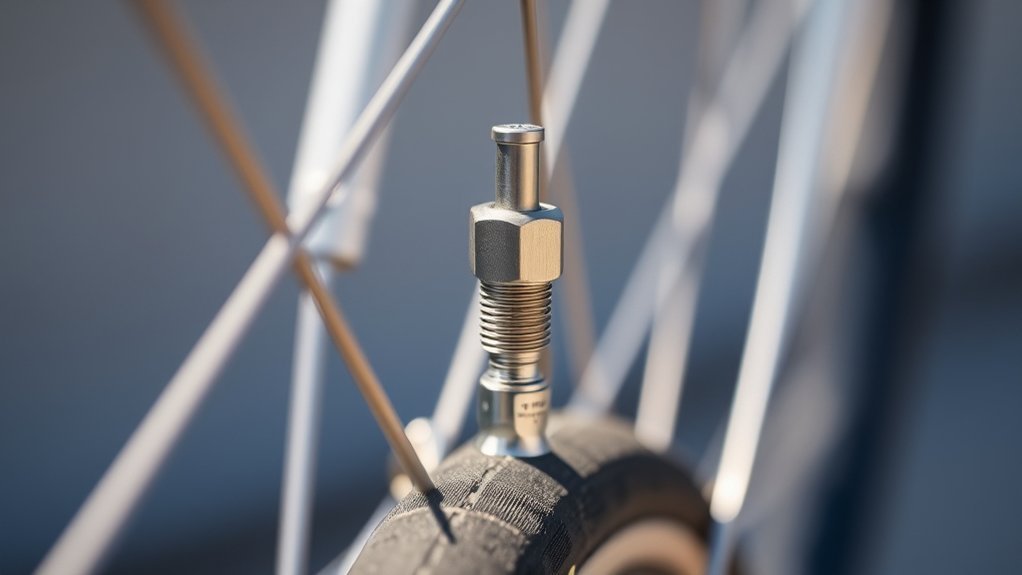

A Presta valve is a narrow, 6 mm-diameter valve invented by Frenchman Étienne Sclaverand and designed for high-pressure, lightweight bicycle wheels. You’ll find the Presta valve on road bikes and high-end rigs because its slim valve body fits smaller rim holes, preserving the strength of lightweight bicycle rims while allowing higher tire pressure—often up to around 8 bars. You’ll value the threaded stem and screw lock-nut that create a secure seal; air pressure itself helps keep the valve closed. Some Presta valves have removable valve cores, so you can add sealant for tubeless setups or perform quick maintenance without swapping tubes. Compared with Schrader valves, Presta valves are lighter and speed up inflation, which matters when you’re chasing efficiency and freedom on the road. In short, the Presta valve optimizes rim integrity and tire pressure control, giving you a reliable, high-pressure solution that supports performance and the liberty to ride harder, farther, and lighter.

Inflate and Deflate a Presta Valve (Tools & Quick Steps)

Grab your pump and dust off the valve cap: inflating or deflating a Presta valve is quick once you know the steps. Remove the valve cap, unscrew the brass lock-nut until it stops, and press the valve tip briefly to release trapped air before attaching the pump head. If your pump head accepts both standards you’re set; otherwise fit a Presta-to-Schrader adapter. Inflate to the recommended pressure, watching the tire and feeling resistance, then detach the pump head and screw the lock-nut down.

To deflate, fully unscrew the lock-nut, press the tip gently to let air out slowly, and stop when you reach your target pressure; reseal the lock-nut and replace the valve cap. For maintenance, keep the valve cap on when not in use, check for leaks, verify the lock-nut turns smoothly, and replace the valve core or inner tube if air loss persists. This keeps your freedom to ride without surprises.

How Presta Valves Work (Parts, Sealing, Threaded Stem)

When you look closely at a Presta valve you’ll see a slim, threaded stem and a small brass lock-nut that work together to let air in and keep it sealed under pressure; unscrewing that nut and pressing the valve tip opens the airflow. You rely on the threaded stem and captive nut to control air flow precisely, and the valve’s 6 mm diameter lets it pass through narrow bicycle rims without weakening them. Presta valves use air pressure to keep the inner valve shut—so inflated tires stay sealed until you choose to deflate. Some cores are removable, letting you add sealant for tubeless setups or perform quick repairs.

| Part | Function | Benefit |

|---|---|---|

| Threaded stem | Controls airflow | Precise inflation |

| Lock-nut | Secures seal | Prevents leaks |

| Removable core | Serviceability | Tubeless-ready |

Unscrew the lock-nut to inflate or deflate; press the tip to release air gradually and safely.

Presta vs Schrader: When to Choose Each Valve Type

Although both valves let you inflate a tire, you’ll pick Presta for narrow, high-pressure road wheels and Schrader for wider, lower-pressure or casual-use rims. You’ll choose by matching valve design to riding goals: lightweight bicycles and performance cycling benefit from the 6 mm Presta valves and small rim hole that preserve strength and handle high-pressure tires (up to ~8 bars). Schrader valves, at 8 mm, suit mountain bikes, casual cycling, and budget bikes where ease of use and compatibility with standard pumps matter; they rely on a spring to seal.

Choose Presta for narrow, high‑pressure road wheels; choose Schrader for wider, lower‑pressure or casual-use rims and easy pumps.

- Performance cycling — Pick Presta valves for aerodynamic rims, high-pressure tires, and minimal rim hole weakening; they keep air pressure sealed via the valve body.

- Mountain bikes and casual cycling — Choose Schrader valves for robustness, simple pumps, and lower typical pressures (2–3 bars).

- Mixed or commuter use — Convert or choose based on pump access and rim compatibility to stay free on the road.

Maintaining and Troubleshooting Presta Valves (Cores, Extenders, Sealant)

Keep your Presta valves working by inspecting cores, extenders, and sealant regularly: listen for hissing, check that the locknut turns smoothly, and leave the dust cap on to keep grit out. You’ll use removable cores to add sealant into tubed or tubeless setups; remove the core so sealant flows into the tire, then reinstall and tighten to prevent air loss. For deep rims, attach valve extenders to reach the pump easily—verify threads and seating so you don’t strip the valve. In tire maintenance, troubleshoot leaks by isolating the valve: press the core briefly to hear hissing, swap in a known-good removable core or a new inner tube if needed. Keep the valve dust cap fitted whenever you’re not inflating to block debris that causes slow leaks. Use sealant to stop small punctures, but inspect after a ride and replace components showing corrosion or persistent leak. These steps free you from roadside frustration and keep you rolling.

Frequently Asked Questions

How Do You Put Air in a Presta Valve?

You’ll remove the dust cap, unscrew the lock-nut, briefly press to release air, fit an air pump (check air pump types and pump adapter options), pump to air pressure recommendations, tighten, replace cap—note valve maintenance tips, compatibility issues.

What Is the Difference Between a Presta Valve and a Regular Valve?

You get slimmer, higher-pressure Presta versus chunkier Schrader: Presta valve advantages include strength, performance and compatibility with narrow rims; Presta valve disadvantages involve fragile design, specific maintenance, materials, history, design, brands, applications, performance trade-offs.

Do You Need a Special Pump for Presta Valves?

Yes — you’ll need a Presta pump compatibility or adapter; choose based on Presta valve types, pressure and installation. Embrace Presta valve benefits, advantages and accessories, practice Presta valve maintenance, note disadvantages and brief history for liberated cycling.

How Does the Presta Valve Work?

Like a gatekeeper, you open the Presta valve by unscrewing its tip; Presta valve functionality uses valve pressure regulation and valve sealing mechanisms to maintain valve air retention. Presta valve components aid bicycle tire maintenance, installation tips, advantages, applications, valve types comparison.

Conclusion

“A stitch in time saves nine” — don’t ignore your Presta valve. You’ll appreciate its slim, high-pressure design on road and gravel bikes and its threaded stem for secure sealing. Carry a small pump or adaptor, know how to loosen the tiny locknut, and inspect cores, extenders, and sealant periodically. Quick maintenance prevents flats and wasted rides. Be practical: learn basic troubleshooting, keep spare parts, and you’ll stay rolling with minimal fuss.

Leave a Reply